Process

Rippey PVAc brush products can be assembled 3 distinct ways. The molding, cleaning, and QC process is unique for each desired assembly.

PVAc (sponge-only) brushes are offered to allow the end-user to customize the product to meet their specific needs and application.

Molds can be designed to accommodate various shapes and sizes, including large format products for LCD and solar applications.

Brushes are batch cleaned only.

For applications that require specific tooling, PVAc brushes can be pre-mounted (or pre-assembled) on various mandrels or fixtures to reduce tool downtime and provide a more consistent end-product.

This option also allows the end-user to recycle/reuse their mandrel.

Brushes are batch cleaned and can be subsequently flow through cleaned as an option.

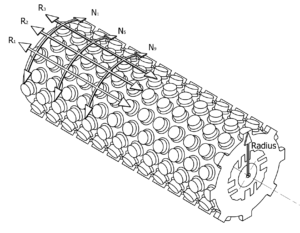

Designed specifically to meet the rigid demands of advanced node (≤28nm) post-CMP cleaning, nanoShear cast-to-mandrel disposable brushes provide unprecedented dimensional uniformity, product consistency, and on-tool reliability.

Brushes are extensively flow through cleaned and can go through an optional nodule treatment process.

- Stable inter-locked brush-mandrel assembly provides low vibration and predictable, consistent torque performance

- Superior dimensional uniformity enables small gap processing without compromising particle removal efficiency

- Uniform contact pressures result in more uniform fluid distribution which reduces point-of-use chemical concentration gradients across the wafer

- Additional proprietary nodule treatment process enables selective fluid flow through the brush nodule

- Controlled nodule morphology hydrodynamically prevents adhesion and agglomeration of unwanted process debris which reduces brush loading, wafer scratching excursions, and increases brush lifetime

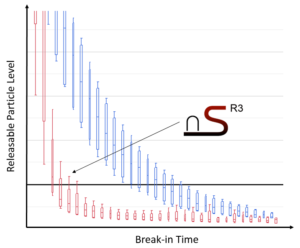

- Incorporates a chemically and mechanically enhanced multi-step cleaning process with improved hydrolysis of the pore templating agent and metal chelation ability

- Includes advanced effluent LPC particle detection, improved quality metrics, and new packaging concept result in a product with the lowest level of releasable and trace metal contamination for improved break-in performance