Applications Support

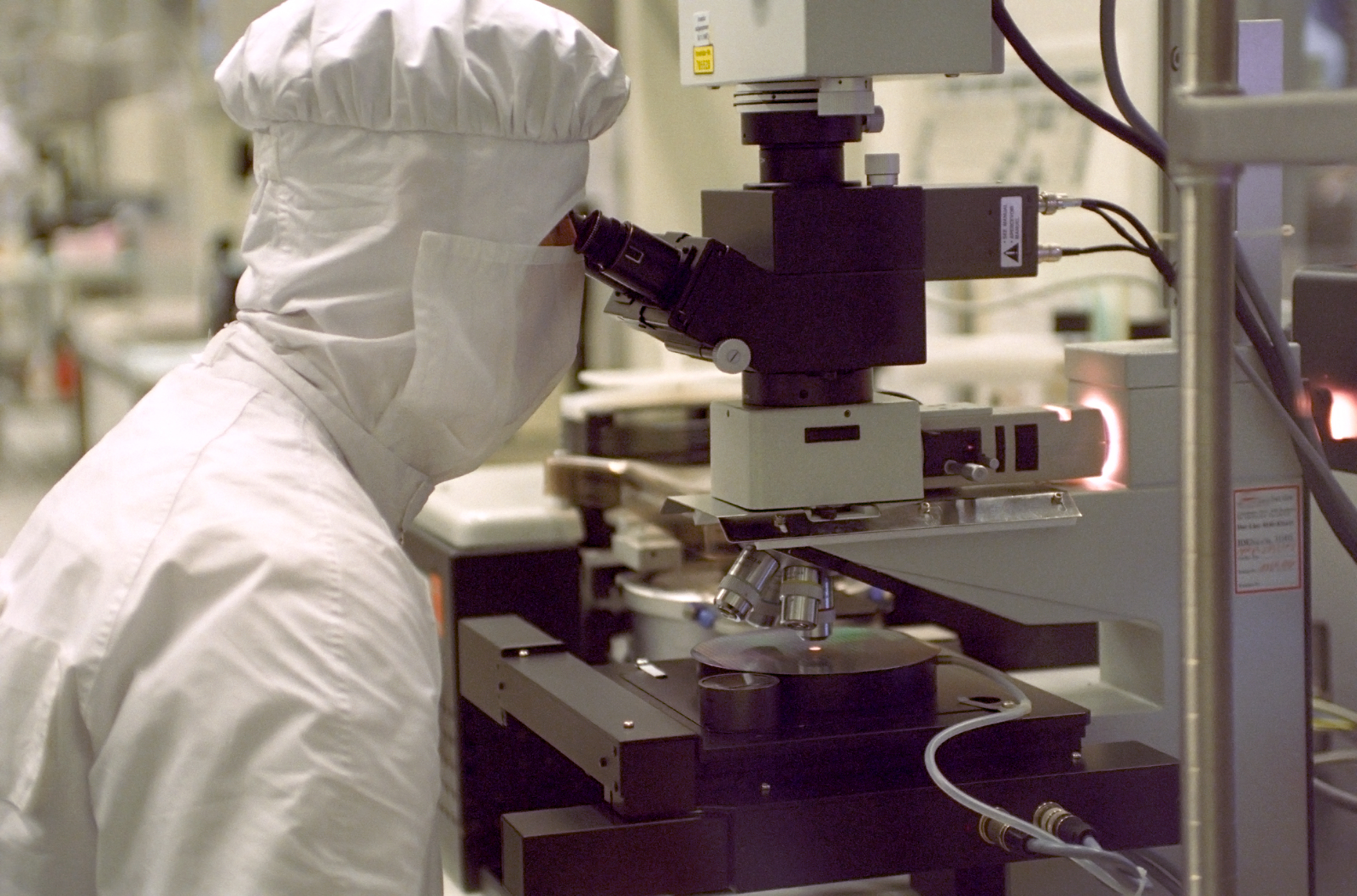

- For today’s advanced process nodes and technologies, synergy between the cleaning system, the chemistry, and the PVA product is paramount

- The Rippey applications engineering team is able to provide onsite global collaboration and support with customers, OEM's, and related consumable suppliers

- Process development and troubleshooting

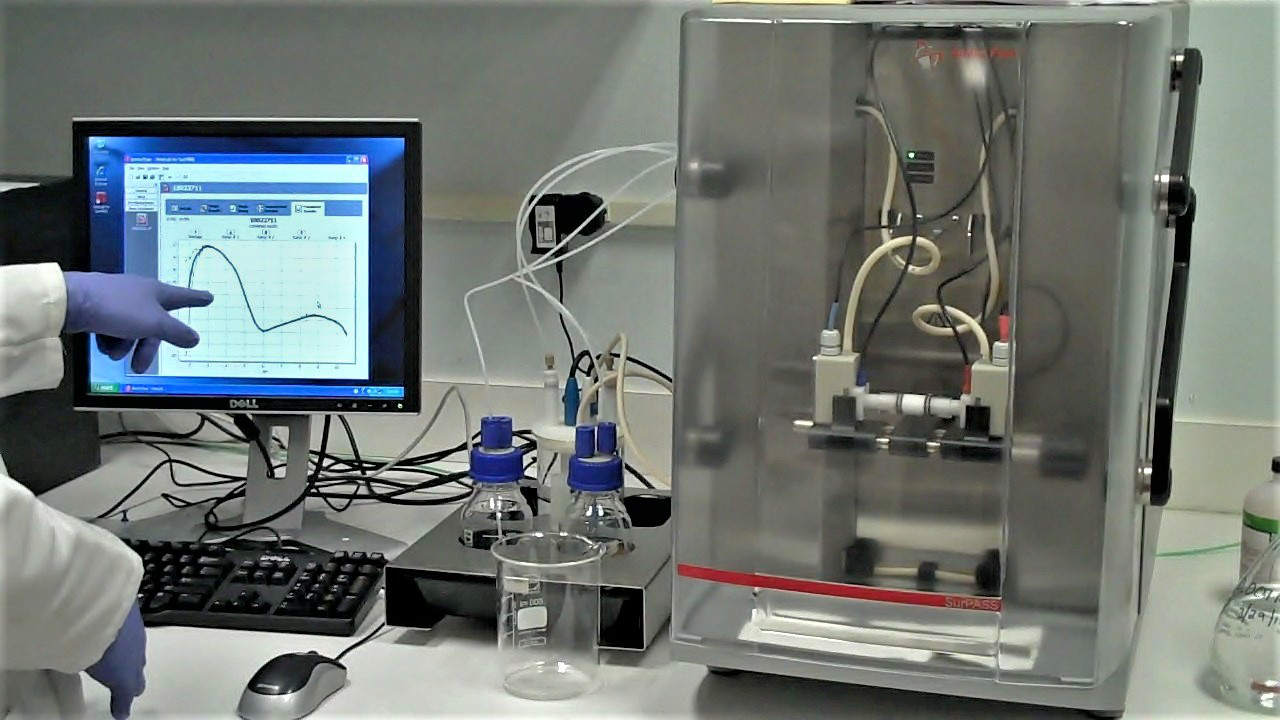

- Interpretation and analysis of performance data

- Materials engineering solutions typically require lab-scale, fundamental research and development

- In conjunction with the ITW Innovation Center, Rippey employs a stage-gate approach to process and product innovation

- Rippey also offers an extensive array of analytical resources and testing services for new and existing customers

- Chemistry-PVA brush compatibility testing

- Material characterization and failure analysis

- Process modeling

Rapid Prototyping

- With growing applications for PVA contact cleaning, Rippey understands the need for developing customizable parts

- Rippey staff of certified professional engineers are able to quickly design parts and mechanical assemblies with 3D solid modeling tools

- Rapid prototyping of molds, specialty tooling, and fixtures is possible with an onsite, fully-outfitted machine shop

Contact: APPLICATIONS@RIPPEY.COM